I have no idea what

pic or part number might help.

are you sure it is lower gear lube that you are seeing?

did you smell it?

lower gear lube stinks like no other oil

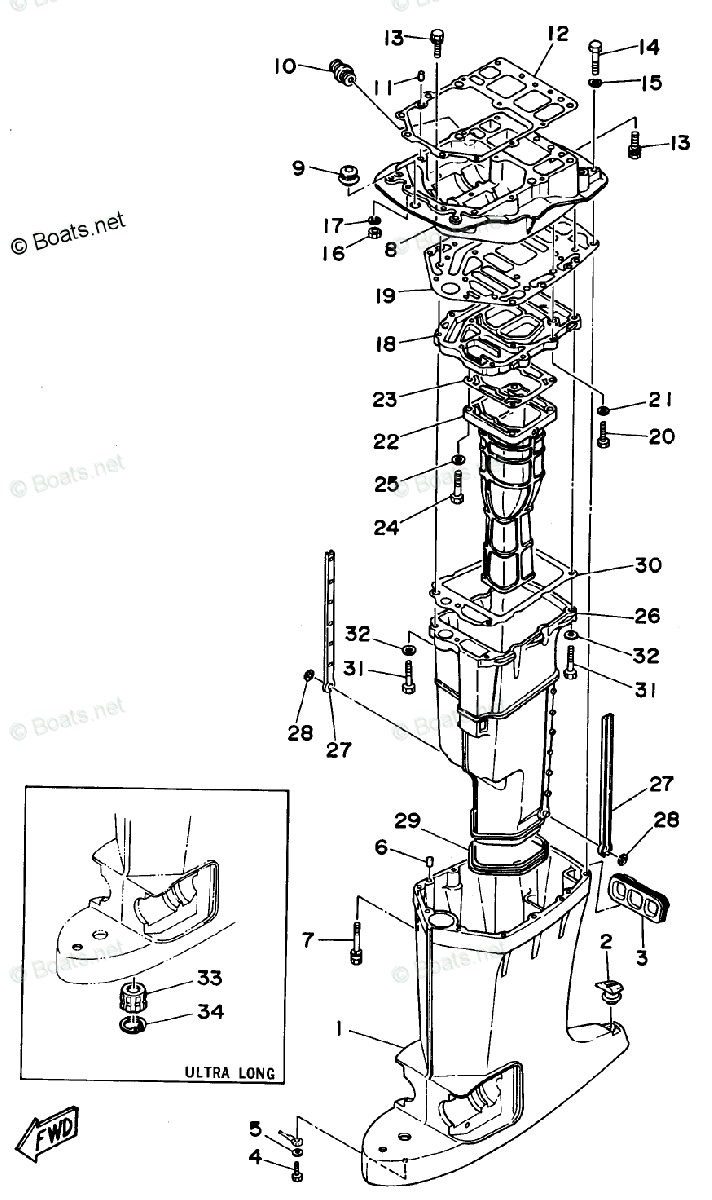

the rubber cupped almost hexagon looking gasket

you are talking about.pic or part number might help.

are you sure it is lower gear lube that you are seeing?

did you smell it?

lower gear lube stinks like no other oil

Comment