The alarm went off on my 1994 Yamaha ProV 115 when I pushed it to WOT. I brought it down to idle speed and the alarm turned off in less than 1 minute. The water pressure was reading a bit lower than normal, and the water temperature was like only 5-10 degrees higher than normal. Like 150 degrees. The engine can run all day at 3400-3800 rpm my normal operating range, but when WOT the alarm goes off.

I checked the impeller and it was formed round, so I installed a new impeller, O-rings, and gasket. I tested it on the water and the water pressure was better than ever, and the water temperature was under 145. BUT when I pushed it to WOT, the alarm went off again after like 1 minute.

I have a water temperature gauge as well as a water pressure gauge(both aftermarket), both senders are mounted on top of the heads with the Yamaha MAR-WPRES-TR adapters, the sender for water pressure is on the port side and the sender for temperature is on the starboard side.

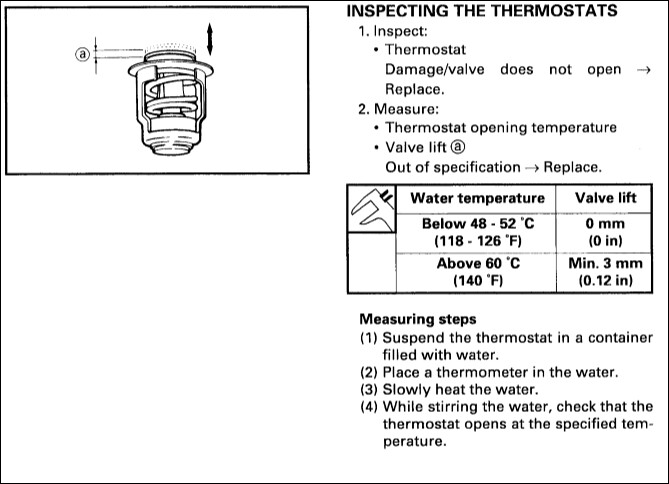

My next step is to check the T-stats and if they are OK, I see no option but to remove the heads and see the condition of the water passages. Since the temperature gauge sender is on the starboard side, and it does not show a high temperature , I am going to disassemble the port side first.

Any advice?

I checked the impeller and it was formed round, so I installed a new impeller, O-rings, and gasket. I tested it on the water and the water pressure was better than ever, and the water temperature was under 145. BUT when I pushed it to WOT, the alarm went off again after like 1 minute.

I have a water temperature gauge as well as a water pressure gauge(both aftermarket), both senders are mounted on top of the heads with the Yamaha MAR-WPRES-TR adapters, the sender for water pressure is on the port side and the sender for temperature is on the starboard side.

My next step is to check the T-stats and if they are OK, I see no option but to remove the heads and see the condition of the water passages. Since the temperature gauge sender is on the starboard side, and it does not show a high temperature , I am going to disassemble the port side first.

Any advice?

Comment