Originally posted by cpostis

View Post

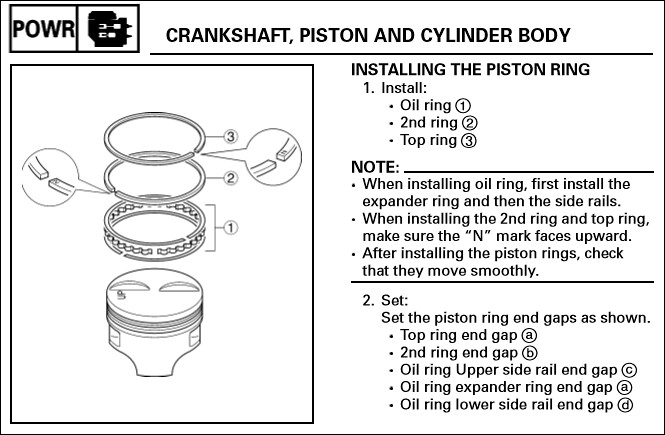

F9.9PistonRings by Charles Postis, on Flickr[/IMG]

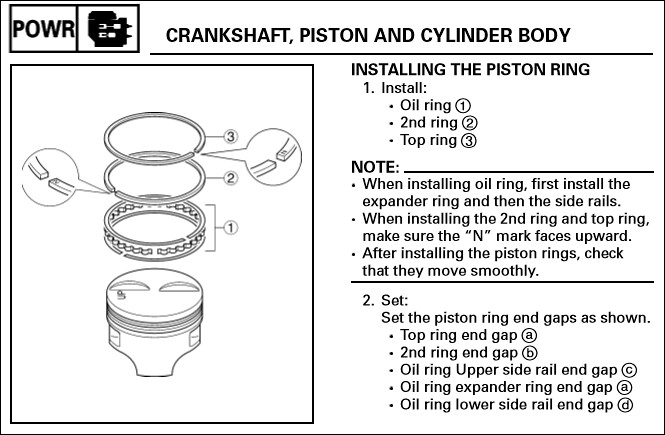

F9.9PistonRings by Charles Postis, on Flickr[/IMG] F9.9PistonRings by Charles Postis, on Flickr[/IMG]

F9.9PistonRings by Charles Postis, on Flickr[/IMG]

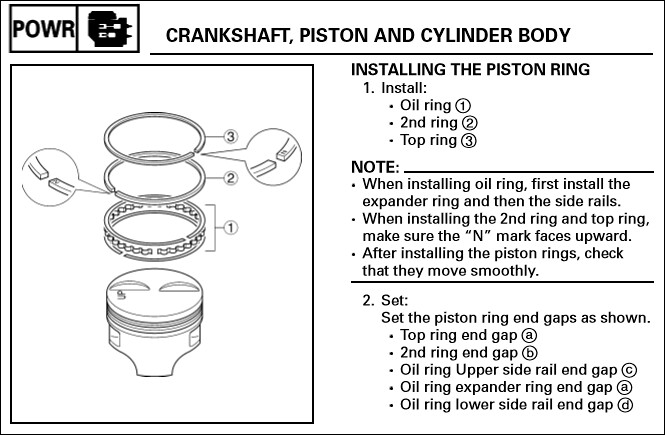

F9.9PistonRings by Charles Postis, on Flickr[/IMG]

F9.9PistonRings by Charles Postis, on Flickr[/IMG]

Comment