So the time has come. One engine refused to come back down after raising it. I pulled the drain/access bolt and added some ATF or power steering fluid (I can't recall which) and it worked just fine. However, as the bolt was out is spit out some fluid. The fluid had been compromised with water.

I had assumed this was the case since I saw a sheen on the water the last time I ran the boat. The sheen was evident after trimming the engine up a bit while I was loading it on the trailer.

I found the correct tool part no AMT - 0004. 38mm X 4mm. Amazon vendors will tell you that they all fit every outboard motor ever produced on this planet. Of course the actual REVIEWS will tell you just how wrong that information is and just how crappy most of these tools are. The pins are soft. The wrench is made from pot metal. So I kept at it till I found the real deal....

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

Pretty solid reviews and a lot of them.

Now comes the tricky part -

WHICH SEALS do I replace and why doesn't YAM sell a little baggie with ALL of them in it? There are numerous vendors selling "kits" but I don't trust them at all. Lousy parts, lousy fit, etc. This is a fairly involved job when I am doing 4 trim cylinders so I'd rater do it ONCE.

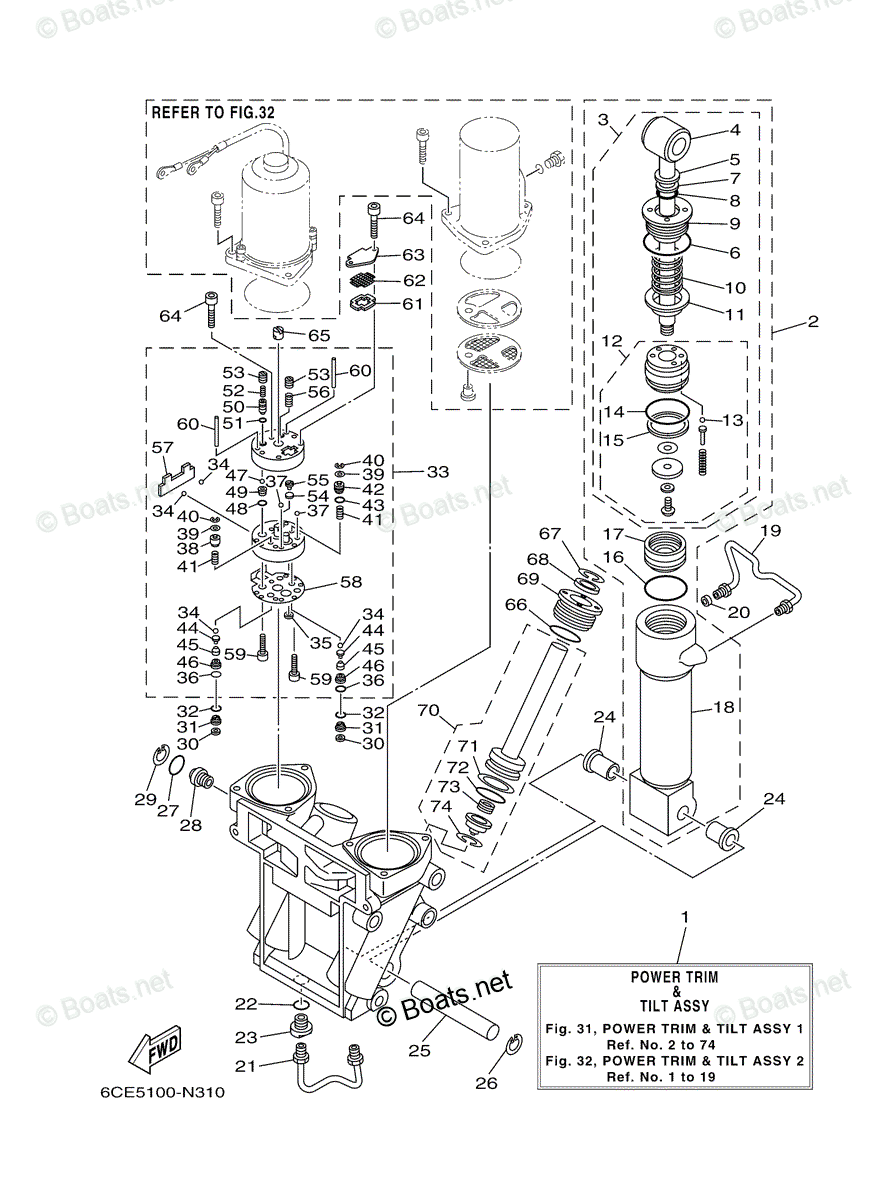

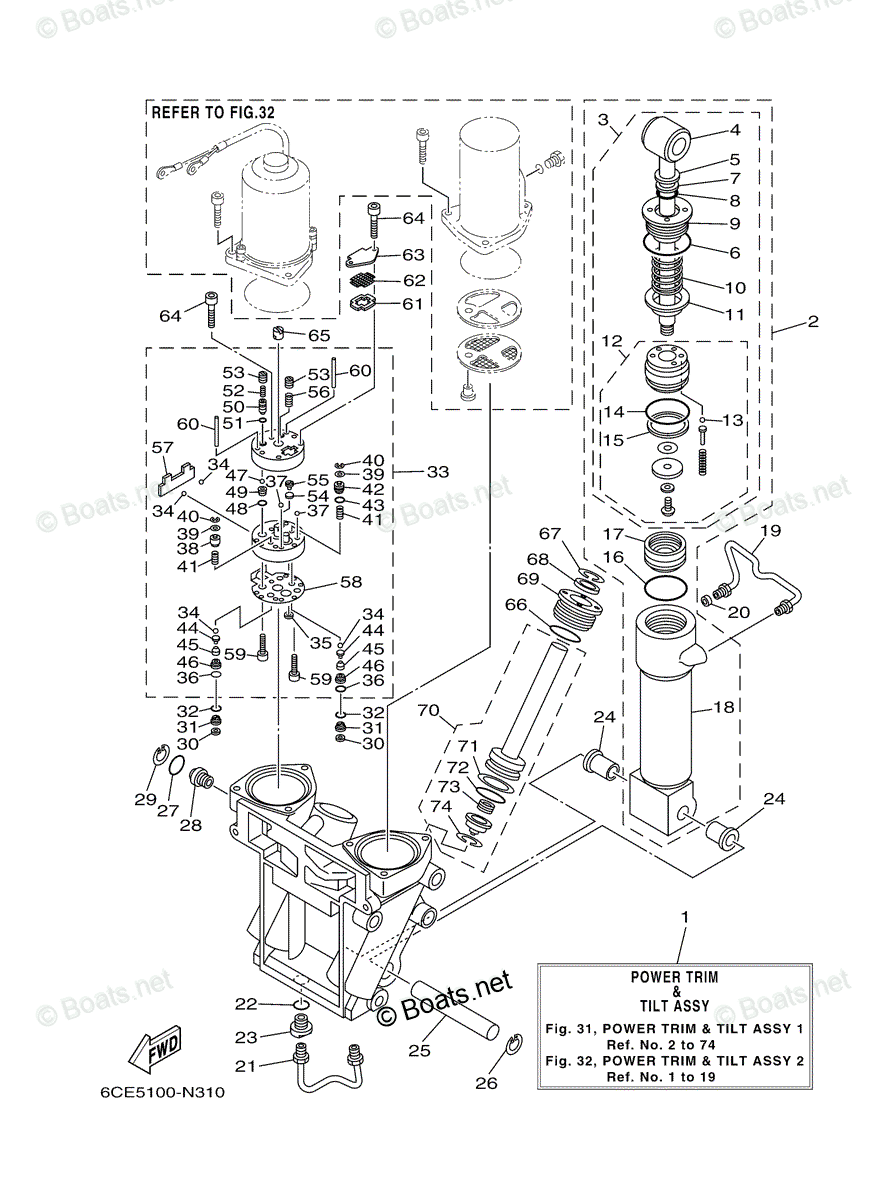

Since the same fluid runs both the 2 TRIM actuators and the 1 TILT actuator that tells me that the ingress could be from one of 3 seals. The tops of the trim cylinders (part no 66) and the top of the TILT (no.6).

Questions -

1. Can/should I just do the trim cylinders, since their tops appear "oily" or do I need to do the tilt as well?

2. Do I have to mess with the seals below the trim rams as well or just the leaky cap? I can't see where else the water could be getting in.

3. How about that little "pipe" at the bottom? It looks like it is a possible fluid transfer/PSI conduit. It's little O rings (part no. 22) could be leaking.

4. Besides YAM miracle jizz, is ATF or PS Fluid a suitable replacement?

5. For those of you who have done it, how tough is this job?

Thanks for any input.

I had assumed this was the case since I saw a sheen on the water the last time I ran the boat. The sheen was evident after trimming the engine up a bit while I was loading it on the trailer.

I found the correct tool part no AMT - 0004. 38mm X 4mm. Amazon vendors will tell you that they all fit every outboard motor ever produced on this planet. Of course the actual REVIEWS will tell you just how wrong that information is and just how crappy most of these tools are. The pins are soft. The wrench is made from pot metal. So I kept at it till I found the real deal....

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

Pretty solid reviews and a lot of them.

Now comes the tricky part -

WHICH SEALS do I replace and why doesn't YAM sell a little baggie with ALL of them in it? There are numerous vendors selling "kits" but I don't trust them at all. Lousy parts, lousy fit, etc. This is a fairly involved job when I am doing 4 trim cylinders so I'd rater do it ONCE.

Since the same fluid runs both the 2 TRIM actuators and the 1 TILT actuator that tells me that the ingress could be from one of 3 seals. The tops of the trim cylinders (part no 66) and the top of the TILT (no.6).

Questions -

1. Can/should I just do the trim cylinders, since their tops appear "oily" or do I need to do the tilt as well?

2. Do I have to mess with the seals below the trim rams as well or just the leaky cap? I can't see where else the water could be getting in.

3. How about that little "pipe" at the bottom? It looks like it is a possible fluid transfer/PSI conduit. It's little O rings (part no. 22) could be leaking.

4. Besides YAM miracle jizz, is ATF or PS Fluid a suitable replacement?

5. For those of you who have done it, how tough is this job?

Thanks for any input.

Comment