Hi All. I'm about to order a replacement balancer assembly for my 2006 F150 serial number 63P-1042463. This engine has just 400 hours fresh water use but recently has started whining/whirring at idle when the engine is cold. Stethoscope puts the noise from the balancer, so I'm doing it now before it fails totally and takes out the powerhead.

Couple of questions. The Yamaha website gives me an updated balancer part number 63P-11500-03-00. This website gives me the old part number 63P-11500-01-00, presumably with the problem gear set. I don't want to end up with the problem gears again.

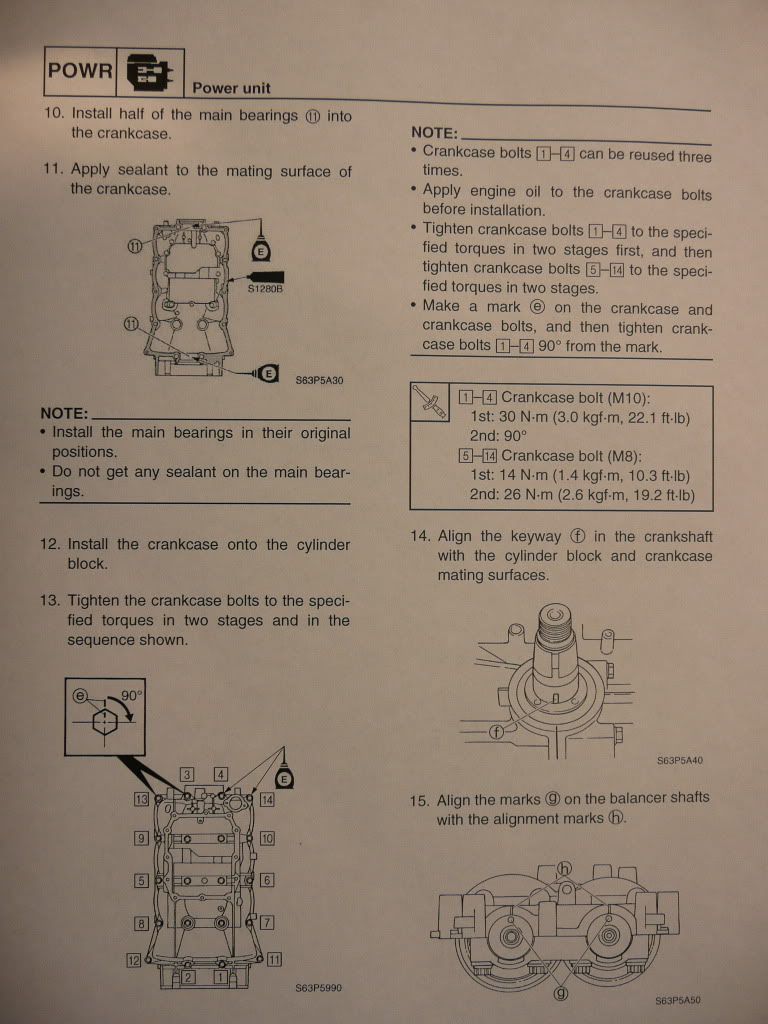

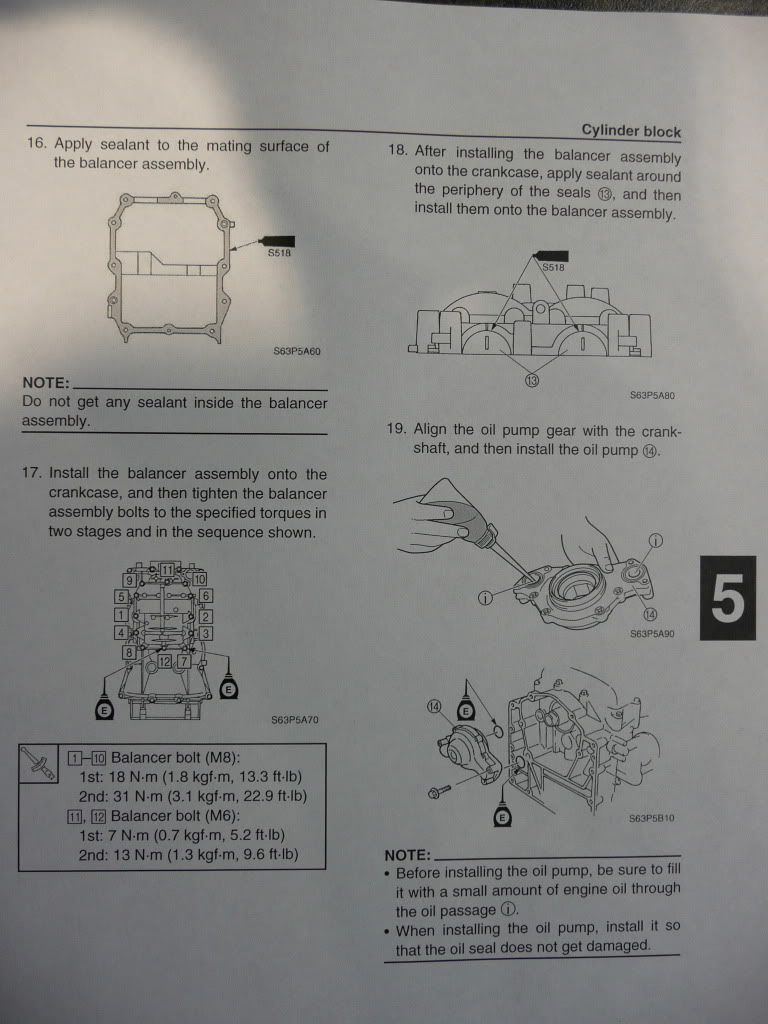

Also, my Yamaha manual specifies a "sealer" be applied to the crank cover seals and another product be applied to the balancer mating surface, but the manual is unclear. I'm assuming RTV black where the balancer mounts to the block and Hi-tack for the seals but could use some help getting the right product.

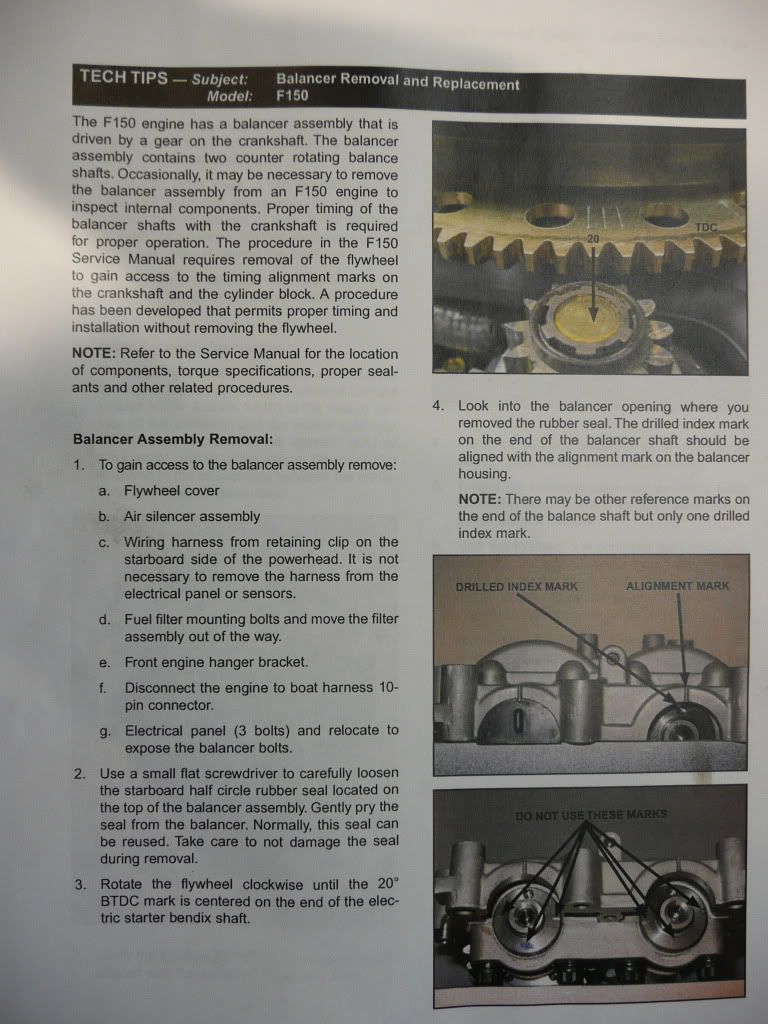

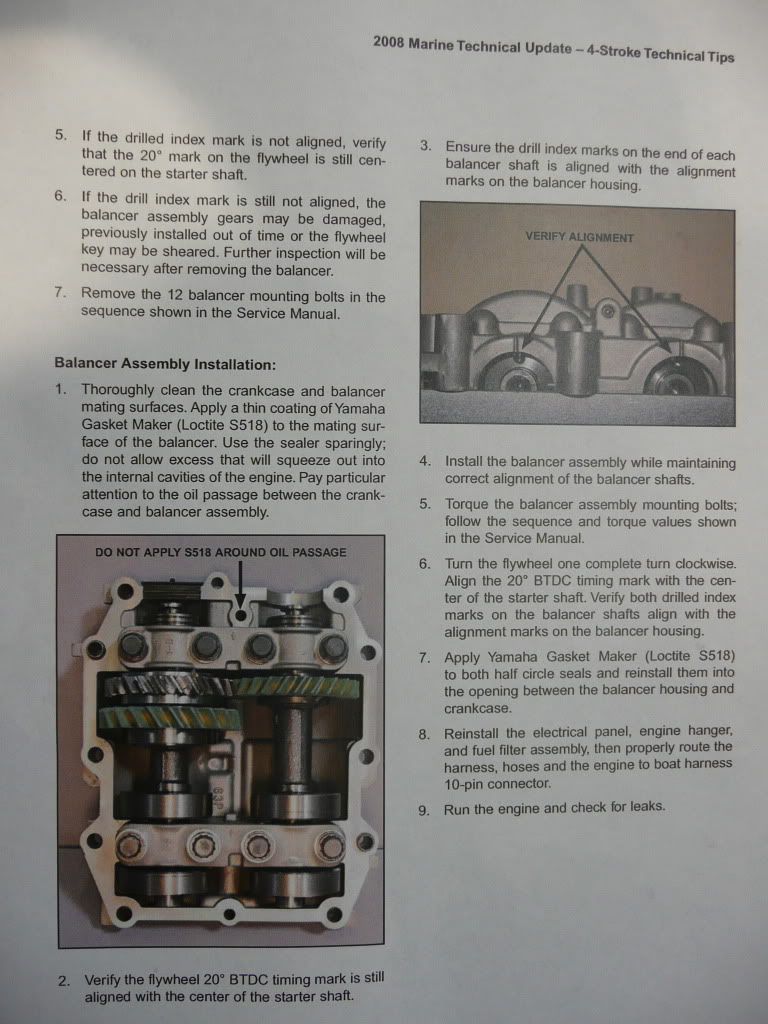

Finally, I would like to change the Balancer assembly without pulling the flywheel. Just call me lazy and the belt is pefect. I have gone through the manual several times and I think I would be OK if I set the crank at TDC with the cam marks indexed. This should be the correct position to index with the balancer assembly markings?

Thanks in advance for your help.

Bill

Couple of questions. The Yamaha website gives me an updated balancer part number 63P-11500-03-00. This website gives me the old part number 63P-11500-01-00, presumably with the problem gear set. I don't want to end up with the problem gears again.

Also, my Yamaha manual specifies a "sealer" be applied to the crank cover seals and another product be applied to the balancer mating surface, but the manual is unclear. I'm assuming RTV black where the balancer mounts to the block and Hi-tack for the seals but could use some help getting the right product.

Finally, I would like to change the Balancer assembly without pulling the flywheel. Just call me lazy and the belt is pefect. I have gone through the manual several times and I think I would be OK if I set the crank at TDC with the cam marks indexed. This should be the correct position to index with the balancer assembly markings?

Thanks in advance for your help.

Bill

Comment