Announcement

Collapse

No announcement yet.

Spark Plug Torque--Not By Hand!

Collapse

X

-

Rodbolt discussed this at one time. Referred to them as fire rings. I believe he did say to replace.

-

I recently saw one in O'rielys. It had a 1/4" drive with ft-lb torque starting at 1. Think it was $25. But if you look on ebay you'll find cheaper.Originally posted by pstephens46 View PostAnybody have a recommendation on a "light" torque wrench? My lowest torque setting is 10 lb ft. Many bolt requirements are less than that. Maybe I am looking in all the wrong stores...

Leave a comment:

-

Agreed, but if a torque wrench is not able to be used because it will not fit due to clearance, IMO you can reach your goals in what I stated in my other post in this thread. After all, what your are doing is crushing the "crush gasket" to seal the combustion chamber not much more. If you consider what overtightening will be and recognize it, you can achieve the goals. Bottom line, although not precise, experience by comparing torqueing with a torque wrench and that by hand "feel" can prevent negative results.Originally posted by boscoe99 View PostI can't.

Tests have been conducted on numerous occasions with the results being that virtually no one can adequately torque a fastener anywhere near specifications. They are almost always over tightened.

Which is why aircraft mechanics have to use a torque wrench. By law. A torque wrench that has been calibrated within the last year. And which has not been dropped since last calibration. Failure to use a torque wrench can result in fines or worse. Someone gets killed due to a fastener not being torqued and the mechanic can (should?) go to jail. Lose his license and his livelihood.

Now in a marine application no one is probably going to die. And lack of use of a torque wrench certainly helps the sale of helicoils. But torque wrenches being so cheap it does not make sense IMO to not use one.

Now, who replaces "crush gaskets", as recommended when re-using a spark plug?

Leave a comment:

-

I can't.Originally posted by cpostis;129763

I'm fortunate enough that I can use my torque wrench on all 6 plugs. I can get a "feel" on what how tight I should make them for the torque specified if I did not have a torque wrench. [BI'm sure you guys can also.[/B]

Tests have been conducted on numerous occasions with the results being that virtually no one can adequately torque a fastener anywhere near specifications. They are almost always over tightened.

Which is why aircraft mechanics have to use a torque wrench. By law. A torque wrench that has been calibrated within the last year. And which has not been dropped since last calibration. Failure to use a torque wrench can result in fines or worse. Someone gets killed due to a fastener not being torqued and the mechanic can (should?) go to jail. Lose his license and his livelihood.

Now in a marine application no one is probably going to die. And lack of use of a torque wrench certainly helps the sale of helicoils. But torque wrenches being so cheap it does not make sense IMO to not use one.

Leave a comment:

-

That's what I have but a much older model.. Still very accurate!Originally posted by cpostis View PostI have a Craftsman # 44593 that measures in inch-pounds , seems it's not available any more. They have another model in this link:

http://www.sears.com/craftsman-micro...000P?rrec=true

You may have to convert from foot-pounds to inch-pounds. "1 foot pounds = 12 inch pounds"

Leave a comment:

-

I have a Craftsman # 44593 that measures in inch-pounds , seems it's not available any more. They have another model in this link:Originally posted by pstephens46 View PostAnybody have a recommendation on a "light" torque wrench? My lowest torque setting is 10 lb ft. Many bolt requirements are less than that. Maybe I am looking in all the wrong stores...

http://www.sears.com/craftsman-micro...000P?rrec=true

You may have to convert from foot-pounds to inch-pounds. "1 foot pounds = 12 inch pounds"

Leave a comment:

-

Anybody have a recommendation on a "light" torque wrench? My lowest torque setting is 10 lb ft. Many bolt requirements are less than that. Maybe I am looking in all the wrong stores...

Leave a comment:

-

^^^, NGK's plugs have a coating on the threads that state DO NOT coat with anti-seize as it's not needed (and changes the actual torque-it'll be higher)

Leave a comment:

-

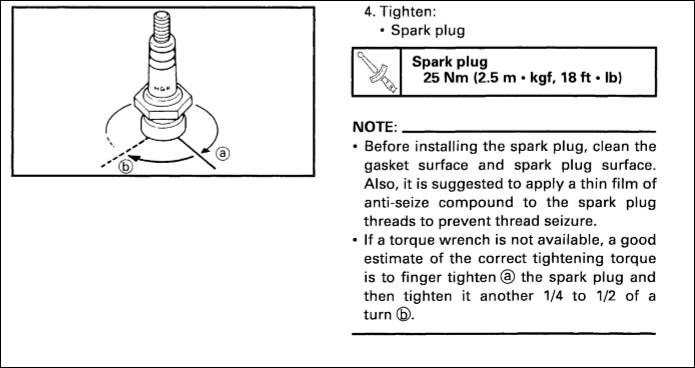

What do you guys want to do? I would think:- seal the combustion chamber from leaking through the spark plug bore

- prevent the spark plug from backing out

- prevent the spark plug threads from being damaged

Here's what my manual says:

[IMG] Spark Plug by Charles Postis, on Flickr[/IMG]

Spark Plug by Charles Postis, on Flickr[/IMG]

I'm fortunate enough that I can use my torque wrench on all 6 plugs. I can get a "feel" on what how tight I should make them for the torque specified if I did not have a torque wrench. I'm sure you guys can also.

Screw the "hand/finger tight" stuff, Get a handle on it and do your feeling like on your first date at first base. Go from there!

Leave a comment:

-

"hand tight" doesn't mean anything to me on my F225,

with the plugs deeply recessed between the cam cover,

"finger tight" makes more sense

(and I always do start them with my fingers, to make certain they are not cross-threaded)

to be fair,

NGK's "once the gasket has made contact with the head" certainly can't be "seen"

only guessed at based on the perceived resistance to further turning

Leave a comment:

-

Like I mentioned, torquing a used plug tp spec will probably take less turns than a new plug. After about 10-15 hrs of engine use with these new plugs I'll pull them to see their color. I'll then see what torque ill get by hand tightening and snug with wrench. Though I will be surprised if i get near 18lb-ft.

Leave a comment:

-

Exactly!Originally posted by TownsendsFJR1300 View PostNew plugs, with new gaskets, always seem to take MORE turns till the gasket flattens out...

Re-installing OLD (good) plugs, the gaskets already flattened and doesn't take nearly as much turning...

here's a neat little graphic from NGK - note the "number of turns after the gasket makes contact":

new plugs: 1/2 - 2/3 turn

re-used: 1/12 turn

Leave a comment:

-

New plugs, with new gaskets, always seem to take MORE turns till the gasket flattens out...

Re-installing OLD (good) plugs, the gaskets already flattened and doesn't take nearly as much turning...

Sparks plugs on mine are spec'ed at 18.4 ft lbs...

!8.4 felt very tight to me when I last changed them out (bout a year ago) but the wrench I have is pretty accurate and I had no issues...

If anything, I'm light on the wrench by hand.

It's like the oil drain plug (for mine it's 20' lbs DRY).

How do you get those threads bone dry to get an accurate torque?

It's not load bearing, like the oil filter, spec'ed at 12 FT lbs, that's what I torque the

drain bolt to as well

As a side note, several Yamaha motorcycles (FJR and my current FZ6) which uses the EXACT SAME

SIZE drain bolt and aluminum block call for 30 Ft LBS... The OB is 20 Ft lbs... WTF??

There's several major boo boo's in the YAMAHA FZ6 manual. ie, when checking the valve clearances, it's in the manual to turn the crankshaft Counter Clockwise, BACKWARDS!!!!!

Some common sense with the manual goes a long way....Last edited by TownsendsFJR1300; 12-10-2016, 06:52 PM.

Leave a comment:

-

Sometimes, and maybe not often, you follow the SM and learn that you've been doing it wrong. And that's not to imply the SM is the holy grail, but in this instance of appropriate torque, I would think the listed amount is not "suggested" but rather "implied".

How many times do you read rodbolt saying "refer to you SM"? Quite a lot, ya know.

Leave a comment:

-

Originally posted by TownsendsFJR1300 View Post"Good and snug" will do it for the spark plugs..

And that's what I thought too. Next time you're replacing spark plugs pull out your torque wrench. Refer to your SM for plug torque. Screw a plug in "good and snug" by hand as you suggest, then measure its torque. Assuming your engines spark plug torque is similar in lb-ft as mine, I'd be shocked to learn you hit the mark by hand. Or perhaps you have poppey forearms?

Leave a comment:

ÂÂ

Leave a comment: