I started this project 2 days ago when I found a rental place less than 2 miles away with a trailerable engine lift. Got the PH removed and started to disassemble. But the upper and lower mount bolts were so corroded that I had to resort to using heat on the tope ones and cutting the nut on the bottom. After getting everything disassembled I came to the conclusion that had I not had to replace the water tube, I might have got 4 or 5 years out of the exhaust and muffler. The muffler had no breaches at all and there were some noticeable pitting around the top few inches, but there was so much carbon, I could not tell after that except on the lower 3 or 4 inches, there was some pitting. I don't know how anything can get destroyed with all the carbon on everything. It was on all the exterior walls of the oil pan and on the interior of the upper case. So, it was evident that all the exhaust does not go through the exhaust tube and the muffler. Wish I knew what was causing it. Obviously the engine is not running right,

While the engine was up in the air, I checked the gasket surfaced and they were perfect. I'd be inclined to replace the oil pump. All other surfaces were in good condition. I'd be inclined to replace the muffler and the exhaust tube and of course, the water tube..

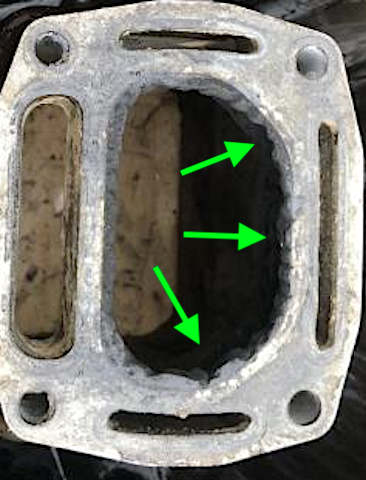

Does anyone know a good carbon remover.. It's a real mess. Anyway I've added some pictures to show the lack of damage. Also, the upper exhaust guide had some corrosion around the exhaust port. I'd be inclined to change that out too. Please tell me what you think.

****

Comment